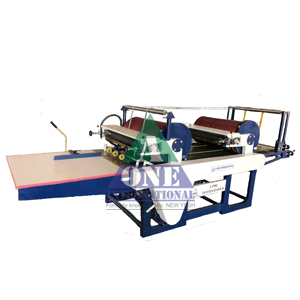

Biodegradable Bag Printing Machine

Biodegradable Bag Printing Machine: High-Quality Printing for Eco-Friendly Bags

A biodegradable bag printing machine is designed to print sharp logos, messages and regulatory details on biodegradable and compostable bags.

Using flexographic technology adapted to bio-based films, it delivers clean, durable prints while respecting the special handling needs of eco-friendly materials.

What Is a Biodegradable Bag Printing Machine?

A biodegradable bag printing machine is a specialised press built for printing on biodegradable and compostable films made from materials such as corn-starch blends, PBAT and other bio-based plastics.

It is engineered to manage the flexibility, thickness and temperature sensitivity of these films so that ink adheres well without damaging the substrate.

Most biodegradable bag printing machines are flexographic, using flexible printing plates and engraved anilox rolls to transfer a controlled layer of ink onto the film surface.

They typically run water-based or low-VOC inks that are compatible with environmental requirements and, where necessary, food-contact regulations

How a Biodegradable Bag Printing Machine Works

In a roll-to-roll configuration, a reel of biodegradable film is unwound, guided through one or more flexo printing units, dried in carefully controlled ovens and then rewound

The printed reels are later converted into shopping bags, garbage bags or liners on a biodegradable bag making machine.

Some integrated systems combine bag making and printing in a single line.

In these setups, the biodegradable bag printing machine forms, seals and prints the bags in one pass, reducing handling and keeping print registration accurate relative to folds, gussets and perforations.

Throughout the process, the machine uses web tension control, edge guiding and registration systems tuned for bio-based films.

This helps keep the material stable, avoid stretching and ensure multi-colour artwork, text and certification logos line up correctly.

Why a Biodegradable Bag Printing Machine Matters

As brands and retailers shift from conventional plastics to biodegradable packaging, print quality becomes a key part of how “green” products are perceived.

A dedicated biodegradable bag printing machine lets companies combine sustainable materials with professional, high-impact graphics.

For compostable and biodegradable bags, printed information such as disposal instructions, certification marks and material descriptions is critical.

Clear, durable printing helps customers understand how to use and dispose of the bags correctly, supporting both compliance and environmental goals.

Key Features of a Biodegradable Bag Printing Machine

The right biodegradable bag printing machine is tuned to the unique behaviour of bio-based films and the demands of eco-friendly packaging.

When evaluating options, focus on features that protect the material while still delivering strong, consistent prints.

|

|

|

|

|

Many biodegradable bag printing machines also offer servo drives, quick-change plate systems, digital counters and recipe-based job settings.

These features help reduce setup time, maintain stable quality and make it easier for operators to run repeat jobs accurately.

Business Benefits of a Biodegradable Bag Printing Machine

For converters and manufacturers, a biodegradable bag printing machine enables reliable, large-scale production of printed eco-friendly bags.

Once a job is dialled in, it can run long orders with consistent adhesion, colour density and registration, helping to control costs and minimise waste.

For brand owners and retailers, it ensures every biodegradable bag carries the same strong visual identity and clear environmental messaging.

That consistency builds trust with customers, supports sustainability claims and turns each biodegradable bag into a visible statement of the brand’s environmental commitment.

Choosing the Right Biodegradable Bag Printing Machine

Choosing the best biodegradable bag printing machine starts with understanding your film types, bag formats, certification needs and production volumes.

Consider how many colours you require, whether you need stand-alone printing or integrated printing and bag making, and what level of automation fits your team.

By matching these requirements with a biodegradable bag printing machine purpose-built for eco-friendly materials, you can turn sustainable bag printing into a reliable, scalable part of your packaging strategy.

With the right machine in place, every biodegradable bag becomes both an environmentally responsible choice and a powerful carrier for your brand.